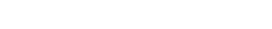

Vertical type single disc grinding machine

GRS series

A vertical single grinding machine is a grinding machine in which a grinding wheel shaft is vertically disposed only on the upper side, and grinds one side of a workpiece. Vertical single disc grinders are generally used to process workpieces with complicated shapes, tighter tolerances and location requirements.

Corresponding work pieces

- Automobile parts (engine, transmission, power steering, hybrid, brake parts)

- Compressor parts

- Industrial robots and FA-related products

- Other knives, etc.

Target materials

- Iron, sintered metal, non-ferrous metal

- Nonmagnetic materials (ceramics, plastics, etc.)

SPEC

| Model | Wheel Diameter | Size | Weight | Main Motor |

|---|---|---|---|---|

| GRS-90 | φ90mm | W1,400 × L1,500 × H2,540 | 7,500Kg | 5.5kW |

| GRS-305 | φ305mm | W1,400 × L1,500 × H2,540 | 4,500Kg | 5.5kW |

| GRS-355 | φ355mm | W1,400 × L1,500 × H2,540 | 4,500Kg | 7.5kW |

| GRS-450 | φ455mm | W1,900 × L2,640 × H2,610 | 7,000Kg | 15kW |

| GRS-510 | φ510mm | W3,080 × L2,450 × H2,200 | 12,000Kg | 37kW |

| GMT-450 | φ455mm | W2,960 × L2,250 × H2,560 | 8,000Kg | 22kW |

PROCESSING METHOD

-

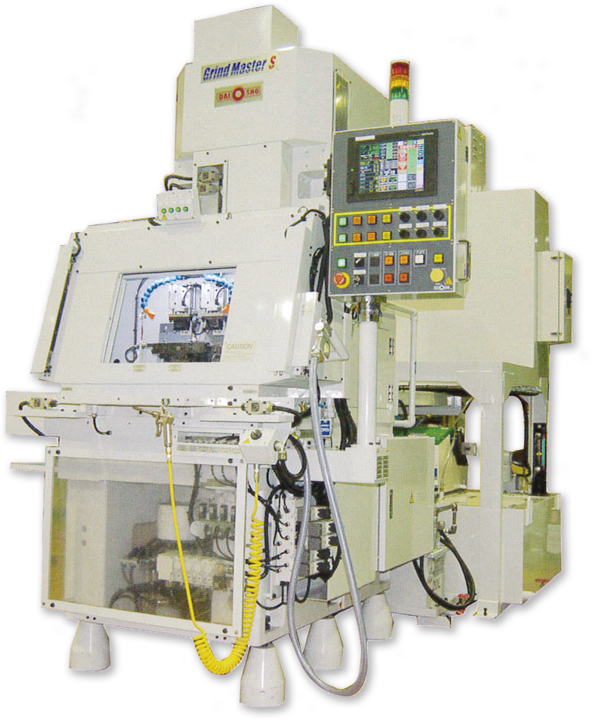

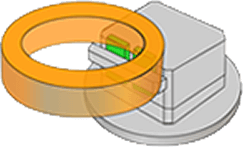

Single-sided Index Table (IT2) Pattern 1

In-feed grinding is combined with forced work rotation while the work piece is clamped on the fixtuere. It also works well for workpieces with tall or complicated shapes.

e.g., pump covers, bearings, etc. -

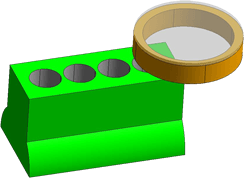

Single-sided Index Table (IT2) Patterns 2

In-feed grinding is combined with forced work rotation while the work piece is clamped on the fixtuere. It also works well for workpieces with tall or complicated shapes.

e.g., pump covers, bearings, etc. -

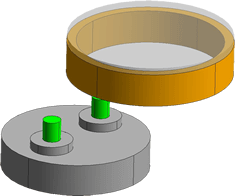

Single-sided Index Table (IT2) Patterns 3

The in-feed grinding is performed by force rotating. It is suitable for workpieces that require high precision. Multiple pockets can reduce the cycle time.

e.g., connecting rods, cam rings, rotors, gears, cylinders, etc. -

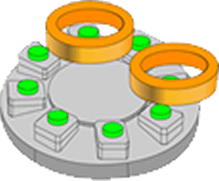

Single-sided Index Table (IT4) Pattern 1

In-feed grinding is combined with forced work rotation while the work piece is clamped on the fixtuere. It also works well for workpieces with tall or complicated shapes.

e.g., pump covers, bearings, etc. -

Single-sided index table oscillation method (IT1)

In-feed grinding is combined with oscillation while the work piece is clamped on the fixture.

e.g., connecting rod mating surface, etc. -

Single-sided rotary index table (IT8)

Target work: Connecting rod

The following requirements and shapes can be handled.

・ different stock removal for each side.

・Steps on the faces like stepped connecting rodsA connecting rod clamped on the fixture of the rotary table is fed to the grinding wheel. The twin spindle model is capable of completing the rough and finish grinding on one machine.

-

Table traverse method (T)

The workpiece on the table traverses to the grinding wheel. It is suitable for large-sized workpieces with a large grinding area.

e.g., engine block, cylinder head, etc.

Other grinding methods are available upon your requests.

In the past 70 years of experience, we have ground a variety of workpieces

to meet the requests of our customers.

Please contact us with any questions or for additional information.